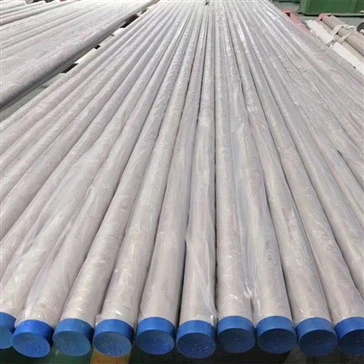

Pipe and Tube

What is Pipe And Tube

Steel pipe is durable, rust resistant, easy to install and highly customizable, making it a top choice in a wide range of industries including construction, shipbuilding, textile, agricultural, oil and gas, and more.

1) The construction industry

Since steel pipe is both durable and lightweight, it's commonly utilized by the construction industry in commercial and residential buildings, as well as in industry sectors including power, water, sewer, manufacturing and more. Steel pipe is also a top choice in the construction industry because it's resistant to rust and corrosion, meaning that it won't require frequent repairs or replacement. This is especially important in water, plumbing and electrical systems, since leaks or breaks in the steel pipe can be both dangerous and costly.

2) The oil and gas industry

Steel pipe is ideal for use in extreme conditions such as corrosive environments, low and high temperatures and high pressure. For this reason, steel pipe is prevalent in the oil and gas industry, especially in pipes like gathering lines (the tubes that transport oil or gas from the producing area to a storage facility or larger main pipeline), and pipe trunk lines (the welded, large-diameter steel pipes that are used to transport natural gas over long distances). Because of steel pipe's durability and versatility, it can stand up to the unique needs of the oil and gas industry.

3) The shipbuilding industry

The strength of steel makes it a great option for ship building since it withstands vibrations, shock and high pressure. Unlike other metals, steel with bend rather than break in extreme conditions, which means it's less likely to crack or leak. In the shipbuilding industry, steel pipe is designed and manufactured for the boilers, super heaters and pressure systems of a ship.

4) The textile industry

The versatility of steel pipe makes it a popular choice in the textile industry for the production of bale openers, mixers, carding machines, spinning machines, winding machines and texturing machines.

5) The agricultural industry

Steel pipe is frequently used in agricultural fittings due to its durability and ability to withstand pressure. Steel is also sometimes mixed with carbon to create a more lightweight yet sturdy agricultural fitting. Farmers and other agricultural organizations use steel pipe in dozens of applications, including tractor engines, grain elevators, field drainage systems, fertilizer applications, vent pipe systems and more.

6) Industrial applications

Steel pipe is a common choice in manufacturing facilities, warehouses and other industrial locations because it's rust-proof and doesn't corrode, affording facilities a lifetime of dependable use. Round steel tubing is often used to transport liquids or gas from one area of an industrial facility to another, as well as in the construction of industry structures itself.

Categories

Send Message

Why Choose Us

Customer Service

We earn your respect by delivering on time and on budget. We built our reputation on exceptional customer service. Discover the difference it makes.

One-Stop Service

We promise to provide you with the fastest reply, the best price, the best quality, and the most complete after-sales service.

Quality Certification

All of our products are up to CE ROHS, TUV and FCC standards.

State-Of-The-Art Technology

We use the latest technology and tools to deliver high quality services. Our team is well-versed in the latest trends and advancements in technology and uses them to provide the best results.

Competitive Pricing

We offer competitive pricing for our services without compromising on quality. Our prices are transparent, and we do not believe in hidden charges or fees.

Customer Satisfaction

We are committed to delivering high quality services that exceed our clients' expectations. We strive to ensure that our clients are satisfied with our services and work closely with them to ensure their needs are met.

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure. It has excellent corrosion resistance, high temperature strength, and oxidation resistance, and is widely used in industries such as chemical, petroleum, metallurgy, and nuclear energy. With the industrialization process and increasing demand, the production and application of nickel alloy pressure vessel forgings are becoming increasingly important.

In production and application, we should actively control the quality to ensure the safety and reliability of nickel alloy pressure vessel forgings. Firstly, we need to strengthen standards in design, manufacturing, and testing to ensure that forgings comply with national and industry standards. Secondly, we need to strengthen the management of process control, material selection, and mechanical processing to ensure that every step meets the standard requirements. Finally, we need to strengthen on-site management and maintenance to ensure the safe and reliable operation of forgings and avoid accidents.

At the same time, we also need to continue promoting technological innovation and improving the performance and technical level of nickel alloy pressure vessel forgings. We can strengthen research in materials, processes, and equipment, master new production technologies and equipment, improve production efficiency and product quality, and reduce costs. This will help promote the development of the industry and make greater contributions to national energy security and economic growth.

In short, nickel alloy pressure vessel forgings play an important role in modern industry. We should actively promote their production and application, strengthen quality management, technological innovation, and maintenance, ensure their safe and reliable operation, and make positive contributions to promoting the high-quality development of the industry.

What are the benefits of stainless steel compared to pure iron

For many years, iron has been the standard material for various applications, including construction and engineering. However, in recent years stainless steel has become increasingly popular as an alternative to iron. There are several reasons for this change, including that stainless steel is more durable and corrosion-resistant than iron. In addition, stainless steel is also easier to clean and maintain than iron. As a result, it is no surprise that many contractors and engineers are now turning to stainless steel as their preferred material

Stainless steel is more resistant to corrosion

Stainless steel is a popular material due to its high resistance to corrosion and staining compared to pure iron. In addition, it is highly durable and can withstand extreme weather conditions, making it an ideal choice for outdoor furniture and other items exposed to the elements.

Stainless steel also has aesthetic value, giving items a modern, stylish appearance. Due to its excellent properties and aesthetics, stainless steel is increasingly used in various products ranging from cutlery and cookware to aircraft. Its advantages ensure that stainless steel remains one of the most sought-after materials in many industries.

Stainless steel is also easier to clean

Stainless steel is becoming popular for appliances and decorations due to its luster and longevity. It also offers several advantages; the smooth surface is one of them. This makes cleaning more accessible, as the soft texture significantly reduces any residue clinging to it. Stainless steel doesn't require a lot of cleaning, which allows you to save time. Furthermore, it is more resilient to scratches and fingerprints that can sometimes spoil your goods. All-in-all, stainless steel provides an alluring look and practicality for your living space or workplace.

Stainless steel does not rust as easily

Stainless steel is a highly sought-after material for several applications. Due to its ability to resist corrosion, it is beneficial in areas prone to moisture. Unlike pure iron, which is more vulnerable to rusting and other forms of decay, stainless steel has enhanced resistance against these elements, making it the preferred choice for wet environments. In addition, its extraordinary strength and malleability further broaden its use, making stainless steel an excellent choice for durable objects or structures in areas with frequent exposure to water or other corrosive sources.

Stainless steel is also more durable than pure iron

Stainless steel provides much higher durability than pure iron. It can withstand rust and corrosion better, meaning it won't need to be replaced nearly as often as pure iron. Another advantage of stainless steel is that it does not require painting or other maintenance protocols, making its use even more cost-effective in the long run. This makes stainless steel ideal for many applications, from kitchenware to public infrastructure components. Its strength and longevity mean it can provide an invaluable service for decades.

Stainless steel has a higher resistance to heat than pure iron

Stainless steel is a remarkable material that offers a variety of benefits over plain iron. Its resistance to corrosion and rusting has made it a popular choice for industrial projects, bridges, and buildings. But above all, stainless steel has one quality that sets it apart from other materials: its heightened resistance to high temperatures. This makes stainless steel an ideal choice for high-temperature environments as its durability won't be compromised by extreme heat, ensuring the safety of those working around it. This enhanced resistance has made stainless steel an invaluable addition to many industries.

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure. It has excellent corrosion resistance, high temperature strength, and oxidation resistance, and is widely used in industries such as chemical, petroleum, metallurgy, and nuclear energy. With the industrialization process and increasing demand, the production and application of nickel alloy pressure vessel forgings are becoming increasingly important.

In production and application, we should actively control the quality to ensure the safety and reliability of nickel alloy pressure vessel forgings. Firstly, we need to strengthen standards in design, manufacturing, and testing to ensure that forgings comply with national and industry standards. Secondly, we need to strengthen the management of process control, material selection, and mechanical processing to ensure that every step meets the standard requirements. Finally, we need to strengthen on-site management and maintenance to ensure the safe and reliable operation of forgings and avoid accidents.

At the same time, we also need to continue promoting technological innovation and improving the performance and technical level of nickel alloy pressure vessel forgings. We can strengthen research in materials, processes, and equipment, master new production technologies and equipment, improve production efficiency and product quality, and reduce costs. This will help promote the development of the industry and make greater contributions to national energy security and economic growth.

In short, nickel alloy pressure vessel forgings play an important role in modern industry. We should actively promote their production and application, strengthen quality management, technological innovation, and maintenance, ensure their safe and reliable operation, and make positive contributions to promoting the high-quality development of the industry.

Tubing in every size

One of the reasons why stainless steel tubing is used in so many different ways is because it can be custom-manufactured in an extensive range of sizes and configurations. While some manufacturers specialize in a certain size, others like Atlantic Stainless have the facilities and technology to fabricate it in tiny sizes for use as hypodermic tubing, all the way up to very large sizes for use as pipes and industrial tubes. It's incredible to imagine that the same product can serve so many potential purposes when its size is changed! The measurements that come into play when choosing the ideal size of tubing for any given application are wall thickness, inner diameter, and outer diameter. Once those are chosen then the tube can be welded and drawn or cut and formed in any length!

Surface Treatment Methods Of Stainless Steel Pipe Fittings

Stainless steel pipe fitting manufacturers will polish and draw the surface when producing pipe fittings. Both of these are better ways to treat the surface of pipe fittings. The pipe fittings themselves are also better, and the service life will be extended. Let's take a look at the specific content.

🌟Surface polishing

The surface-polished bright tube has a bright and clean appearance and is easy to clean. It has an invisible protective film that can prevent the surface of the tube from being corroded. It is not easy to accumulate scale and has a longer service life.

🌟Brushing treatment

The advantage of the matte surface drawing pipe is that it has an elegant appearance and less light pollution. After drawing treatment, the rust prevention is sufficient for the indoor environment.

👍Anti-rust and corrosion-resistant

The reason why stainless steel pipes are rust-proof and corrosion-resistant is that there is a nickel component on the surface of stainless steel pipes, which forms an oxide layer on the surface for protection.

👌Improve aesthetics

When polishing and drawing the surface of stainless steel pipe fittings, it is to better process the surface of the pipe fittings, which not only improves the aesthetics and reduces rust during use, but also increases the overall use value and extends the service life in the future. , it is also more durable to use and its versatility will be enhanced.

Our Factory

ONE-STOP service, we also provide beveling, polishing, welding, hemming, bending, drilling, cutting, rolling and some finished product processing, such as tanks, etc. Our products are widely used for industries of petroleum, chemical engineering, nuclear power, marine vessel metallurgy, sewage disposal, aviation and aerospace etc.Quality Assurance:Our laboratory can perform all the test including Chemical Composition Test, Machanical Properties Test, Hydrostatic Test, Eddy Current Test, Ultrasonic Test, 100% X-ray Test, Impact Test, Hardness Test, Flattening Test and so on. YuShen has been certificated by ISO 9001 2015, as well as PED and we can ensure the products are 100% inspected before delivery. If necessary, we can accept the third party inspect, like SGS, BV, TUV.YuShen is committed...

Certificate Of Honor

FAQ

Q: What is stainless steel forging?

A: The stainless steel forgings process amplifies the existing qualities of stainless steel, delivering an enhanced look and feel. The forging process improves the corrosion resistance of stainless steel, permitting the grade to endure and withstand harsh, aggressive, and more extreme environments.

Q: What is the difference between casting and forging stainless steel?

A: The difference between casting and forging comes down to the shaping process. Casting reduces metals to a molten form while forging shapes the metal workpiece while in a solid state.

Q: What is forging vs casting knives?

A: Forged steel is generally either hammered or pressed while hot to have a more dense, uniform crystalline structure. This is what makes it harder and more flexible at the same time. Cast steel is just poured hot into a mold and left to cool, or quenched.

Q: Is forging cheaper than casting?

A: Casting is often much cheaper than forging. Both casting and forging have their advantages and disadvantages, so the better method depends upon what is being fabricated.

Q: Can forged steel be welded?

A: Forged steel can be welded by any method steel can be welded gas, electric or laser. Forged steel is just steel and you just have to pick the most convenient method that you have available, whichever one that is.

Q: Are crankshafts cast or forged?

A: Cast crankshafe is one-time shaping process, while forged crankshaft need to be forged many times. And further heat treatment processes are also not the same. From the side of internal organization,the performance of forged crankshaft is more stable than that of cast ctankshaft.

Q: Is forged heavier than cast?

A: Since castings begin as liquid molten metal, they can flow into nearly any shape or size if a mould is available. Another factor to consider is the weight of the components. When two identical parts are made, one by casting and the other by forging, the casting is typically lighter than the forging.

Q: Why use forgings and where are they used?

A: The forging process can create parts that are stronger than those manufactured by any other metalworking process. This is why forgings are almost always used where reliability and human safety are critical. But you'll rarely see forgings, as they are normally component parts contained inside assembled items such a airplanes, automobiles, tractors, ships, oil drilling equipment, engines, missiles and all kinds of capital equipment – to name a few.

Q: Can you forge after casting?

A: Yes in fact it is common for aluminum pulleys to be cast, forged and machined to tolerance. The casting gives you the rough shape, the forging work hardens a critical union like at the hub and then machining brings critical features into tolerance.

Q: Why is forging stronger than casting?

A: In forging, the metal is pounded and deformed, but the grain flow remains unbroken, allowing it to retain its strength. In casting, the metal is melted down, which breaks the grain flow and causes the metal to lose some of its initial strength once it solidifies.

Q: How can you tell if something is forged or cast?

A: Casting and forging are two different types of production. The process of casting involves heating a substance to its melting point and pouring it into a mold, where it solidifies. When something is forged, it is bent into shape physically while staying solid and heated continuously.

Q: Can casted metal be forged?

A: Consequently, cast iron, while resistant to wear, is quite brittle, and cannot be forged. You would have to reduce the carbon content to something around 2% or less, which means that then you have steel, which can be forged.

Q: What metals Cannot be forged?

A: Cast Iron is a metal bearing high strength in compression but weak in tension. It is hard and brittle. So, it cannot be forged.

Q: Why can't you forge cast iron?

A: As its name suggests, however, cast iron is meant solely to be cast; it cannot be forged. Additionally, while it excels in casting capability and in achieving the shape set by the mold, cast iron cannot be reliably welded due to its higher carbon content, which causes a brittle weld.

Q: What temperature do you forge steel?

A: Hot forging of steel: The forging temperatures are above the recrystallization temperature, and are typically between 950°C–1250°C.

Q: What are the four 4 basic types of forging?

A: These are the main types of forging processes: open-die, impression die, cold, and seamless rolled ring. Let's look at four of the different kinds of forging processes and how people use them. For open-die forging, metalsmiths place the workpiece between two flat or simple dies.

Q: Are casted parts stronger than forged parts?

A: Strength: Forged metals have more relative strength than cast and plate metals, even when the parts are formed using the same alloy. Reduced Likelihood of Defects: Other processes may result in metal pieces with shrinkage and cold pour issues, cavities within the cast, or porosity.

Q: What are the limitations of forging?

A: Forging is not without its limitations. There are two primary constraints: Size Limits: Forging has some weight and length limitations, varying based on the equipment used during the process. Generally, the forging process cannot produce very large components like casting.

Q: What happens to steel when forged?

A: As the metal is shaped during the forging process, its internal grain texture deforms to follow the general shape of the part. As a result, the texture variation is continuous throughout the part, giving rise to a piece with improved strength characteristics.

Q: Why do you use borax when forging?

A: Adding borax can improve the processing performance of metal. The right amount of borax can improve the fluidity and plasticity of metal, making it easier to be processed into the desired shape and size during the forging process.

As one of the most professional pipe and tube manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to wholesale customized pipe and tube at low price from our factory. For free sample, contact us now.

Stainless Steel Precision Tube,Stainless Steel Ring Forging,Nickel Alloy Corrugated Pipe