High-Temperature Super Alloy Pipe And Tube

What is High-Temperature Super Alloy Pipe And Tube

High-temperature alloys, also known as superalloys, are reputable for their durability. These alloys perform well regardless of high temperatures, pressures, and other substance-altering circumstances.

Improved strength

Alloys often exhibit greater strength and hardness than pure metals, making them suitable for a wide range of applications.

Enhanced corrosion resistance

Many alloys are more resistant to corrosion than pure metals, making them ideal for use in environments where corrosion is a concern.

Customizable properties

By adjusting the composition of the alloy, engineers can tailor its properties to meet specific requirements, such as conductivity, ductility, or melting point.

Cost-effectiveness

Alloys can be designed to provide desired properties at a lower cost than using pure metals with similar characteristics.

Versatility

Alloys can be engineered to have a wide range of properties, making them suitable for diverse applications across industries such as aerospace, automotive, construction, and electronics.

Categories

Hot Products

-

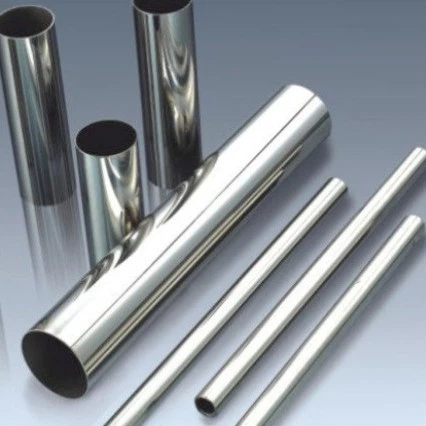

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

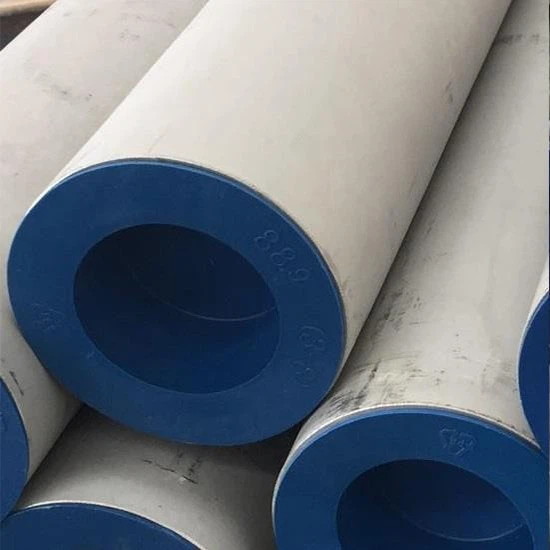

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Why Choose Us

Customer Service

We earn your respect by delivering on time and on budget. We built our reputation on exceptional customer service. Discover the difference it makes.

One-Stop Service

We promise to provide you with the fastest reply, the best price, the best quality, and the most complete after-sales service.

Quality Certification

All of our products are up to CE ROHS, TUV and FCC standards.

State-Of-The-Art Technology

We use the latest technology and tools to deliver high quality services. Our team is well-versed in the latest trends and advancements in technology and uses them to provide the best results.

Competitive Pricing

We offer competitive pricing for our services without compromising on quality. Our prices are transparent, and we do not believe in hidden charges or fees.

Customer Satisfaction

We are committed to delivering high quality services that exceed our clients' expectations. We strive to ensure that our clients are satisfied with our services and work closely with them to ensure their needs are met.

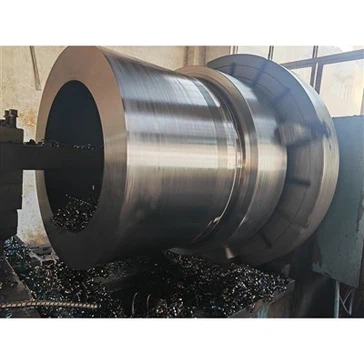

Nickel alloy cylinder forgings are a type of metal product with high strength and corrosion resistance

Nickel alloy cylinder forgings are a type of metal product with high strength and corrosion resistance, widely used in various industrial fields. Its excellent performance and quality provide reliable guarantees for improving production efficiency and ensuring production safety.

Firstly, the production technology of nickel alloy cylinder forgings has gradually matured and continuously improved, reaching a level of high precision and reliability. Due to the precise control of parameters such as temperature, pressure, and time during its production process, the quality of the product is ensured. Meanwhile, due to the continuous advancement of modern mechanical processing technology, the surface quality of products can be made smoother and brighter, greatly improving the appearance quality of products.

Secondly, nickel alloy cylinder forgings have a wide range of applications and have become core materials in various fields such as aviation, aerospace, petrochemicals, and nuclear industry. In the fields of aviation and aerospace, nickel alloy cylinder forgings are key materials that make up important components such as engines, turbines, cooling systems, and steam regenerators; In the petrochemical and nuclear industries, nickel alloy cylinder forgings are mainly used in important high-temperature, high-pressure, and corrosive environments, with extremely high corrosion resistance and tensile strength, ensuring the sustainability, efficiency, and safety of production.

Finally, the development prospects of nickel alloy cylinder forgings are very broad. With the acceleration of economic globalization and technological innovation, demand continues to increase, ushering in new development opportunities. In the future, we can foresee that with the continuous progress of technology and the continuous improvement of the industrial chain, nickel alloy cylinder forgings will become one of the important materials in people's production and life, creating more economic and social value.

In summary, nickel alloy cylinder forgings, as an important metal product, have greatly promoted our industrial development and technological progress due to their excellent performance and wide application prospects. We have reason to believe that with the continuous improvement of technology and the driving force of industrial demand, nickel alloy cylinder forgings will have better development.

How Is Stainless Steel Made

Stainless steel is manufactured by a range of smelting methods that are typical of most metallurgical processing. Three of the common processes are listed below:

An electric arc furnace uses a high current flowing between two carbon electrodes to heat the raw materials. Alloying elements of scrap and pre-made steel, chromium, etc. are added to the furnace crucible, along with iron ore and the necessary additions to refining this component, to create the stainless steel alloy. Melting and refinement occur in the furnace and the impurities float off as slag/clinker.

Blast furnaces melt iron ore mixed with coke in the crucible, blowing oxygen through the molten iron to remove impurities that float off as slag. Once the ore has been purified, chromium and other alloying elements are added to the molten metal to create the stainless steel alloy.

Vacuum induction melting and vacuum arc melting produce very high-purity metals, from already refined source materials (i.e., no ore is added). This process allows for more precision in the control of the composition of stainless steel alloys.

Once the stainless steel has been melted and refined, it will generally be rough cast into billets. These billets are then formed into various shapes and sizes using a range of manufacturing processes, including:

The casting of stainless steel involves molten metal being poured into a cast cavity, to which it conforms and the cast retains the cavity shape when cooled.

Rolling of stainless steel sees the raw billets pass through a series of precise pinch rollers, to reduce their thickness and shape the steel into sheets or other forms. This process can be performed hot or cold, to produce a variety of final materials of diverse strengths and crystalline structures.

The forging of stainless steel requires it to be heated and then shaped by hammering or pressing it into the desired form.

Machining stainless steel enables it to be cut and shaped using various machines, such as lathes and mills.

After the stainless steel has been formed into its final shape, it may undergo additional processing to improve its properties, such as heat treatment, polishing, or coating.

Nickel alloy cylinder forgings are a type of metal product with high strength and corrosion resistance

Nickel alloy cylinder forgings are a type of metal product with high strength and corrosion resistance, widely used in various industrial fields. Its excellent performance and quality provide reliable guarantees for improving production efficiency and ensuring production safety.

Firstly, the production technology of nickel alloy cylinder forgings has gradually matured and continuously improved, reaching a level of high precision and reliability. Due to the precise control of parameters such as temperature, pressure, and time during its production process, the quality of the product is ensured. Meanwhile, due to the continuous advancement of modern mechanical processing technology, the surface quality of products can be made smoother and brighter, greatly improving the appearance quality of products.

Secondly, nickel alloy cylinder forgings have a wide range of applications and have become core materials in various fields such as aviation, aerospace, petrochemicals, and nuclear industry. In the fields of aviation and aerospace, nickel alloy cylinder forgings are key materials that make up important components such as engines, turbines, cooling systems, and steam regenerators; In the petrochemical and nuclear industries, nickel alloy cylinder forgings are mainly used in important high-temperature, high-pressure, and corrosive environments, with extremely high corrosion resistance and tensile strength, ensuring the sustainability, efficiency, and safety of production.

Finally, the development prospects of nickel alloy cylinder forgings are very broad. With the acceleration of economic globalization and technological innovation, demand continues to increase, ushering in new development opportunities. In the future, we can foresee that with the continuous progress of technology and the continuous improvement of the industrial chain, nickel alloy cylinder forgings will become one of the important materials in people's production and life, creating more economic and social value.

In summary, nickel alloy cylinder forgings, as an important metal product, have greatly promoted our industrial development and technological progress due to their excellent performance and wide application prospects. We have reason to believe that with the continuous improvement of technology and the driving force of industrial demand, nickel alloy cylinder forgings will have better development.

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure

Nickel alloy pressure vessel forgings are important equipment that operate under high temperature and high pressure. It has excellent corrosion resistance, high temperature strength, and oxidation resistance, and is widely used in industries such as chemical, petroleum, metallurgy, and nuclear energy. With the industrialization process and increasing demand, the production and application of nickel alloy pressure vessel forgings are becoming increasingly important.

In production and application, we should actively control the quality to ensure the safety and reliability of nickel alloy pressure vessel forgings. Firstly, we need to strengthen standards in design, manufacturing, and testing to ensure that forgings comply with national and industry standards. Secondly, we need to strengthen the management of process control, material selection, and mechanical processing to ensure that every step meets the standard requirements. Finally, we need to strengthen on-site management and maintenance to ensure the safe and reliable operation of forgings and avoid accidents.

At the same time, we also need to continue promoting technological innovation and improving the performance and technical level of nickel alloy pressure vessel forgings. We can strengthen research in materials, processes, and equipment, master new production technologies and equipment, improve production efficiency and product quality, and reduce costs. This will help promote the development of the industry and make greater contributions to national energy security and economic growth.

In short, nickel alloy pressure vessel forgings play an important role in modern industry. We should actively promote their production and application, strengthen quality management, technological innovation, and maintenance, ensure their safe and reliable operation, and make positive contributions to promoting the high-quality development of the industry.

Classification Of Stainless Steel Profiles By Purpose

1. Architectural stainless steel profiles (divided into two types: doors, windows and curtain walls).

2. Radiator stainless steel profile.

3. General industrial stainless steel profiles: mainly used for industrial production and manufacturing, such as automated machinery and equipment, enclosure skeletons, and each company's customized mold opening according to its own mechanical equipment requirements, such as assembly line conveyor belts, elevators, dispensing machines, Testing equipment, shelves, etc. are mostly used in the electronic machinery industry and clean rooms.

4. Rail vehicle structure: mainly used for rail vehicle body manufacturing.

Our Factory

ONE-STOP service, we also provide beveling, polishing, welding, hemming, bending, drilling, cutting, rolling and some finished product processing, such as tanks, etc. Our products are widely used for industries of petroleum, chemical engineering, nuclear power, marine vessel metallurgy, sewage disposal, aviation and aerospace etc.Quality Assurance:Our laboratory can perform all the test including Chemical Composition Test, Machanical Properties Test, Hydrostatic Test, Eddy Current Test, Ultrasonic Test, 100% X-ray Test, Impact Test, Hardness Test, Flattening Test and so on. YuShen has been certificated by ISO 9001 2015, as well as PED and we can ensure the products are 100% inspected before delivery. If necessary, we can accept the third party inspect, like SGS, BV, TUV.YuShen is committed...

Certificate Of Honor

FAQ

Q: What is the major difference between tube and pipe?

A: Tubes can come in different shapes such as square, rectangular and cylindrical, whereas piping is always round. The circular shape of the pipe makes the pressure force evenly distributed. Pipes accommodate larger applications with sizes that range from a ½ inch to several feet.

Q: What is the difference between pipe and tube as per ASME?

A: Pipe is normally used to convey fluids, so the internal cross-sectional area (defined by the ID) is important. Tube is more frequently used in structures so the OD is the important number. Wall thickness under tolerance is up to 12.5% applied for all pipes as and welded fittings as per ASME B16.

Q: Is tube cheaper than pipe?

A: Because of the materials that tubes are constructed from, such as aluminum, mild steel, brass, chrome, copper, or stainless steel, they are usually more expensive than pipes. Obviously, the end user price is influenced by the materials used.

Q: What is pipe size and tube size?

A: Tube is measured by an exact outside diameter (OD) and wall thickness. Pipe is measured by a nominal outside diameter (also known as NPS or Nominal Pipe Size) and wall thickness.

Q: Which is stronger pipe or tube?

A: For applications that require the strongest possible steel, tube is generally the way to go. It's known to be significantly stronger than pipe, and one of the strongest metal formats period.

Q: Why is tube stronger than pipe?

A: Your intuition that the wall thickness and ID/OD effect the strength is correct. But if you have a pipe with identical dimensions as an HSS tube. The HSS(tube) will be stronger because it has higher Fy and higher Fu. Given pipe and tube of same material/strength properties, the manufacturing tolerances also matter.

Q: Why are the ends of pipes bevel before welding?

A: Bevelling pipe ends helps to ensure that these welds are as strong as possible but it can be slow and hold up production when time is critical. Both speed and quality are important – bevelling must take place rapidly so that bottlenecks do not occur, yet it must meet high specifications to ensure welds are strong.

Q: What is the thickness tolerance of ASME tube?

A: Hi, in pipes and fittings thickness calculation(as per ASME B31. 3) for semless pipes we go for mill tolerance of 12.5% in general.

Q: Is pipe measured by OD or ID?

A: The nominal dimension for pipe is the ID. So, 1½ inch pipe is NOT 1½ inch outside diameter, but instead is nominally, (approximately) 1½ inch inside diameter. Pipe is typically manufactured to looser tolerances and less expensive to purchase.

Q: What is the advantage of tube over pipe?

A: Tubing offers greater flexibility in systems with fewer connections, meaning fewer potential leak points. Tubing can usually be installed faster and cheaper than piping. Tubing is cut to length and then deburred, the fittings are tightened onto a nut.

Q: What is the standard diameter of a tube?

A: The most common standard diameters are as follow: 0.5 inch (15 mm), 0.75 inch (20 mm), 1 inch (25 mm), 1.5 inch (40 mm), 2 inch (50 mm), 3 inch (80 mm), 4 inch (100 mm), 6 inch (150 mm), 8 inch (200 mm), 10 inch (250 mm), 12 inch (300 mm), 14 inch (350 mm), 16 inch (400 mm), 18 inch (450 mm), 20 inch (500 mm), 22 inch .

Q: How do you determine tube size?

A: The size is almost always written somewhere on the sidewall of the tyre. Inner tubes typically state a wheel diameter and width range for which they will work, e.g. 26 x 1.95-2.125", indicating that the tube is intended to fit a 26 inch tyre with a width of between 1.95 inches and 2.125 inches.

Q: What is the weakest part of a pipe?

A: The weak point is usually the connections. So, we'll focus today's lesson on pipe connections. Threaded pipe connections: If you look at the threads of a bolt under magnification, you would see that the threads are even along the entire blot.

Q: Which pipe has more pressure?

A: So, a larger line has the potential to carry more water that can result in more stress. Still, smaller pipes have the potential to reach that pressure faster.

Q: How much force can a pipe withstand?

A: Barlow's Formula relates the internal pressure that a pipe can withstand to its dimensions and the strength of its materials. The formula is P= (2*T*S/D), where: P = pressure. S = allowable stress.

Q: How can I make my tube stronger?

A: Thicker wall and bigger diameter put you in the right direction. The most popular suggestion here is filling the tube with concrete. This no doubt will get you a stronger member that is capable in flexing more and take more load without bucking the top or compression side of the tube.

Q: What's stronger square or round tubing?

A: The answer is round tube has a higher resistance to both flex and torsional twisting than square for a given weight. NB. Use ERW tubing as it is much, much stronger than CHS . If you have a round hole, putting the maximum size round tube through it will be stronger than its' square counterpart.

Q: What does PE stand for in steel pipe?

A: PE pipes feature ends typically cut at a 90-degree angle to the pipe run for a flat, even termination. In most cases, plain end pipes are used in combination with slip-on flanges and socket weld fittings and flanges.

Q: What is the end of a pipe called?

A: At the end of any length of pipe, are the pipe ends. The most common pipe ends are: Plain End – for small pipe sizes (typically less than 2 inches (5cm)). Bevel End – for larger pipe sizes. Threaded End – for small pipe sizes (typically less than 2 inches (5cm)).

Q: How do you calculate the thickness of a tube?

A: Having the inside dimensions (ID) and the outside dimensions (OD) will allow you to figure out the wall thickness on the tubing. You would need to subtract the ID from the OD and then divide by two. This number is the wall thickness.

As one of the most professional pipe and tube manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to wholesale customized pipe and tube at low price from our factory. For free sample, contact us now.

Stainless Steel Precision Tube,Stainless Steel Ring Forging,Nickel Alloy Corrugated Pipe