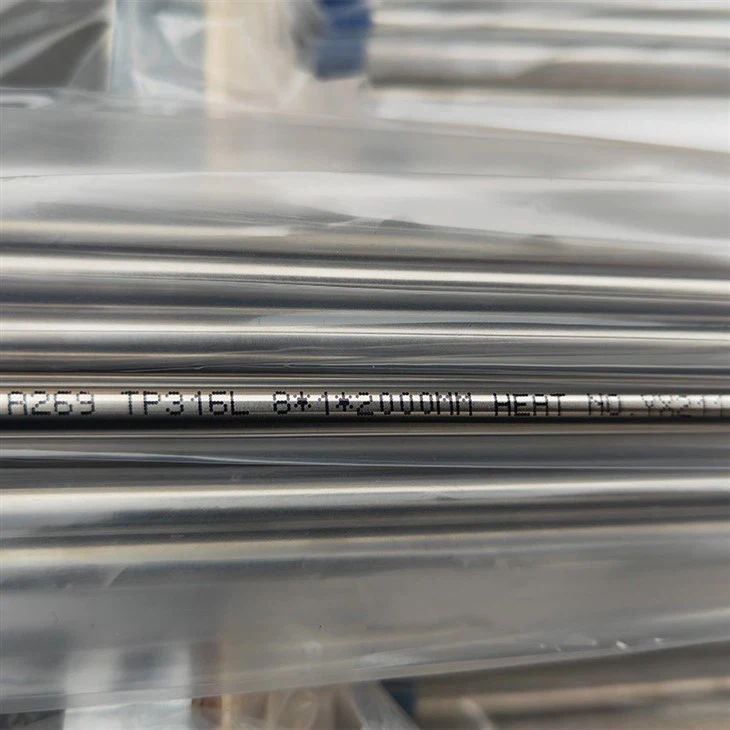

Stainless Steel EP Tube

High smoothness electropolished tube, also known as EP tube. Electrolytic polishing:through electrochemical polishing, can greatly improve surface morphology and structure, resulting in a significant

Description

High smoothness electropolished tube, also known as EP tube. Electrolytic polishing:through electrochemical polishing, can greatly improve surface morphology and structure, resulting in a significant reduction in surface area. The surface is a closed, thick layer of chromium oxide film, with energy close to the normal level of the alloy, and the amount of medium will also be minimized. Industries such as microelectronics, optoelectronics, and biopharmaceuticals generally use bright burning (BA) and electrolytic polishing (EP) products for high-purity and clean pipeline systems that transmit sensitive or corrosive media.

Scope of use:

(1) EP grade pipeline - high-purity gas (5N&6N or above), toxic (PH3 AsH3 SiH2Cl2), corrosive (HCINH3), flammable and explosive (SiH4) gas.

(2) BA General gas N2O2 H2 Ar CDA

(3) AP compressed gas, double casing outer tube

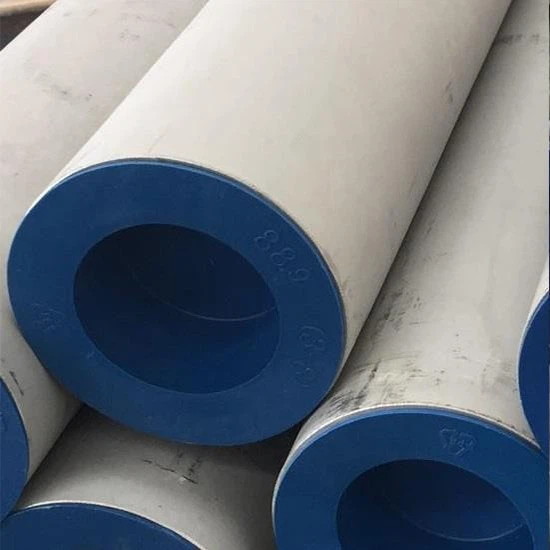

Stainless steel clean pipes are used to transport high-purity or ultra pure gases in the semiconductor industry, as well as clean pipes (various types of water) in the biopharmaceutical industry. Among them, the surface treatment method of stainless steel pipeline system is AP (Annealed&Pickled): that is, acid pickling and passivation. The inner surface of the pipeline will not improve surface roughness after acid pickling and passivation, but can remove residual particles and grease on the surface, reduce energy levels, but will not reduce the quantity of media.

BA (Bright Annealed): refers to bright annealing, which is a high-temperature treatment in a hydrogenation or vacuum state. On the one hand, it eliminates internal stress, and on the other hand, it forms a passivation film on the surface of the pipeline to improve the morphology and structure and reduce energy levels. To some extent, it has improved the surface roughness. (Special gas discharge pipe and general nitrogen)

EP (electro-polished): refers to point polishing, which can greatly improve the surface morphology and structure through electrochemical polishing, and minimize the actual surface area. The surface is a closed and thick chromium oxide film, with energy close to the normal level of the alloy, and the number of working media will also be minimized. Industries such as microelectronics, optoelectronics, and biopharmaceuticals typically use BA/EP products for high-purity and clean pipeline systems that transport sensitive or corrosive media.

Advantages and disadvantages of electrolytic polishing:

Advantages: 1. Ultra smooth, removing shallow surface defects and reducing total surface area

2. The flow channel is parallel to the pipe direction to reduce the accumulation of fine dust, suitable for non planar processed object shapes

3. Reorganize a good passivation layer to reduce the reaction between the fluid and the pipe wall, and improve the corrosion resistance of the pipe fittings

4. No uneven mechanical polishing phenomenon

5. Easy to blow and clean

Disadvantage: 1. Electrolytic polishing belongs to the surface dissolution method for flattening and speed reduction

When encountering poor substrate conditions (such as hot drawn pipes or large-sized cold drawn pipes)

3. Mechanical polishing pre-treatment is still required first

Quality inspection of pipes:

1. Visual inspection inside and outside the pipe

Inspection rate: 100%

Inspection items: There should be no water marks, dirt, uneven grinding, poor electrolysis, or discoloration inside the pipe

2. Surface roughness measurement detection

Inspection rate: 10%

Inspection item: Ra/Rmax

3. White cloth experiment

Pipeline inspection rate: 100%

Inspection item: The white cloth inside the tube must not be dirty or have residual grease

4. Pure water impedance measurement

Inspection rate: 10%

Inspection item: Pure water resistance at the end of the tube>17.5M Ω. cm

5. Particle residue determination

Inspection rate: 1%

Inspection item: Particle

6. Determination of residual oil in the pipe

Inject pure water, seal, shake and shake, let it stand and distill to extract residual oil, and calculate the residual amount

Inspection rate: 1%

Standard value:<0>

The commonly used grades are:

Austenitic Stainless Steel:304,304H,304L,316L,316H,316Ti,317,317L,321,347,347H,347HFG,310S,310H,

Super Austenitic Stainless Steel: S30432,S31042,N0367,904L,Nitronic 40,Nitronic 60,XM-19

Duplex Stainless Steel: 254SMO,F50,2205,F53,F55,F60,F61,F65,S31500,S31803,S32205,S32750,S32760

PH Steel: 15-5PH,17-4PH,17-7PH,13-8MO

Type | Welded / Seamless |

Shape | Square / Rectangular / Round |

Standard | GB,AISI,ASTM,DIN,EN,JIS |

Available Grades | Seamless tube: EN 10216-5, NFA 49-217 |

Seamless and welded tube: ASTM A789 | |

Flanges and valves: ASTM A182 | |

Fittings: ASTM A182; A815 | |

Plate, sheet and strip: ASTM A240, EN 10088-2 | |

Bar and shapes: ASTM A276, A479, EN 10088-3 | |

Forged billets: EN 10088-3 | |

Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. | |

Monel 400 / Monel K-500 | |

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

Thickness | Welded Pipe 0.5mm - 80mm or customized |

Max Length | Welded Pipe 50000mm or customized |

Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

Inspection | TUV,SGS,BV,ABS,LR and so on |

Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

Deformation processing : Bending / Cutting / Rolling / Stamping | |

Welded | |

Forged | |

Delivery Time | 7-40 days |

Trade Term | FOB CIF CFR CIP DAP DDP EXW |

Transportation | By air, by sea, by train, by truck |

Sample | Free |

Warranty | Trade assurance after sales service |

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, stainless steel ep tube, China stainless steel ep tube manufacturers, suppliers, factory, Stainless Steel Oval Tube, Stainless Steel Square Tube, Inconel Series Pipe, Nickel Alloy Circle Forging, Monel Series Pipe, Nickel Alloy EP Tube,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More