Stainless Steel Square Tube

A stainless steel with high nickel and high molybdenum content, containing copper and nitrogen, and a typical microstructure of the base metal composed of 100% austenite is called a super austenitic s

Description

Stainless steel square tube is a hollow strip of steel, called a square tube because its cross-section is square. A large number of pipelines are used for transporting fluids, such as petroleum, natural gas, water, gas, steam, etc. In addition, when the bending and torsional strength are the same, they are lighter in weight, so they are also widely used in the manufacturing of mechanical parts and engineering structures.

Classification of stainless steel square pipes: Square pipes are divided into two categories: seamless steel pipes and welded steel pipes (welded pipes). According to the cross-sectional shape, it can be divided into square and rectangular pipes. Circular steel pipes are widely used, but there are also some irregular steel pipes such as semi-circular, hexagonal, equilateral triangle, octagonal, etc.

Square tube specification: 5 * 5~150 * 150 mm thickness: 0.4~6.0 mm

Square tube material: 304, 304L, TP304, TP316L, 316, 316L, 316Ti, 321, 347H, 310S,etc.

Production process: Round steel preparation → Heating → Hot rolling perforation → Cutting head → Acid washing → Grinding → Lubrication → Cold rolling processing → Degreasing → Solution heat treatment → Straightening → Pipe cutting → Acid washing → Finished product inspection.

For stainless steel square pipes that are subjected to fluid pressure, hydraulic tests must be conducted to verify their pressure resistance and quality. It is considered qualified if there is no leakage, wetting, or expansion under the specified pressure. Some steel pipes also need to undergo edge rolling tests, expansion tests, flattening tests, etc. according to standards or the requirements of the purchaser.

Decorative stainless steel square pipes are widely used in anti-theft nets, gates, and guardrails. The wall thickness requirement for square pipes in building decoration is generally between 0.4~6.0mm, and the pipe diameter requirement is between 5.0~150.0mm. The specific values need to be determined based on the application and pipe diameter size.

Conventional diameter decorative stainless steel square tube: with a wall thickness between 0.4~2.0mm, suitable for anti-theft nets and courtyard fences used in households. The wall thickness is moderate and the load-bearing capacity is moderate. This type of specification is easy to find and purchase.

Medium to large diameter decorative stainless steel square tube: with a wall thickness ranging from 1.5 to 6.0mm, the pipe diameter is relatively large compared to the pipe wall, and the load-bearing and pressure bearing capacity also increase accordingly. It is suitable for buildings in public places, such as lamp posts, pedestrian bridge guardrails, municipal guardrails, etc

Stainless steel pipes have strong ductility, can be polished on the surface, and can be easily welded, so stainless steel pipes can be used for many styling designs.

We can produce and process various shapes and designs for use in furniture, exhibition booths, metal products, metal special equipment, and personalized crafts.

In addition, geological exploration, chemical industry, construction industry production, mechanical engineering, aircraft and automobile manufacturing, including heating furnaces, medical equipment products, home furnishings, and bicycle manufacturing, also require a large amount of various types of stainless steel square tubes.

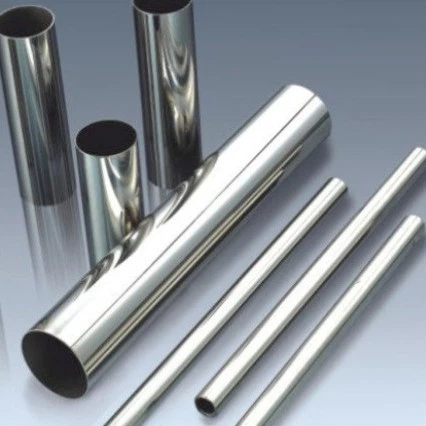

Under normal circumstances, the appearance of stainless steel pipes has a brightness of 400 and a typical metallic texture. However, with further promotion of production and processing, the appearance can be made into a mirror like brightness. Stainless steel pipes can also be treated with matte finish on the surface. Whether it is mirror treatment or metal wire drawing matte treatment, they have made ordinary stainless steel pipes taller and more sophisticated.

The commonly used grades are:

Austenitic Stainless Steel:304,304H,304L,316L,316H,316Ti,317,317L,321,347,347H,347HFG,310S,310H,

Super Austenitic Stainless Steel: S30432,S31042,N0367,904L,Nitronic 40,Nitronic 60,XM-19

Duplex Stainless Steel: 254SMO,F50,2205,F53,F55,F60,F61,F65,S31500,S31803,S32205,S32750,S32760

PH Steel: 15-5PH,17-4PH,17-7PH,13-8MO

Type | Welded / Seamless |

Shape | Square / Rectangular / Round |

Standard | GB,AISI,ASTM,DIN,EN,JIS |

Available Grades | Seamless tube: EN 10216-5, NFA 49-217 |

Seamless and welded tube: ASTM A789 | |

Flanges and valves: ASTM A182 | |

Fittings: ASTM A182; A815 | |

Plate, sheet and strip: ASTM A240, EN 10088-2 | |

Bar and shapes: ASTM A276, A479, EN 10088-3 | |

Forged billets: EN 10088-3 | |

Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. | |

Monel 400 / Monel K-500 | |

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

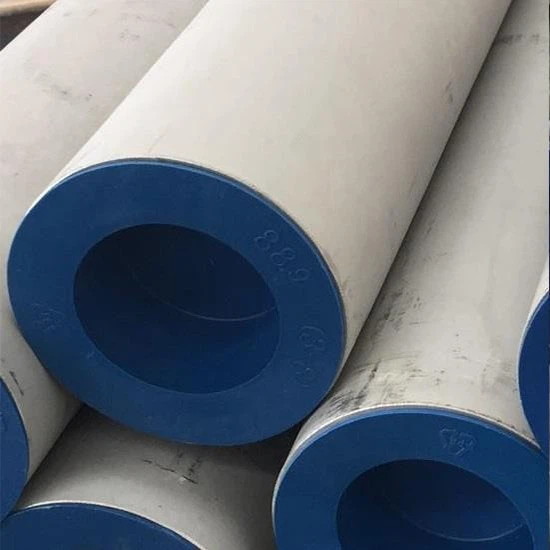

Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

Thickness | Welded Pipe 0.5mm - 80mm or customized |

Max Length | Welded Pipe 50000mm or customized |

Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

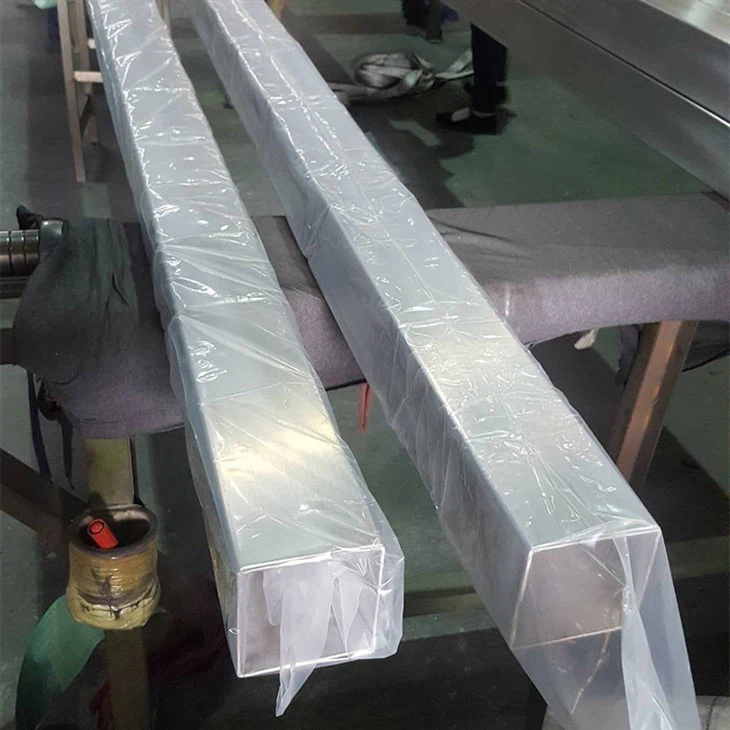

Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

Inspection | TUV,SGS,BV,ABS,LR and so on |

Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

Deformation processing : Bending / Cutting / Rolling / Stamping | |

Welded | |

Forged | |

Delivery Time | 7-40 days |

Trade Term | FOB CIF CFR CIP DAP DDP EXW |

Transportation | By air, by sea, by train, by truck |

Sample | Free |

Warranty | Trade assurance after sales service |

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, super austenitic stainless steel pipe, China super austenitic stainless steel pipe manufacturers, suppliers, factory, Nickel Alloy Precision Tube, Nickel Alloy EP Tube, Stainless Steel Ring Forging, Stainless Steel Precision Tube, Nickel Alloy Capillary T,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More