Super Austenitic Stainless Steel Pipe

A stainless steel with high nickel and high molybdenum content, containing copper and nitrogen, and a typical microstructure of the base metal composed of 100% austenite is called a super austenitic s

Description

A stainless steel with high nickel and high molybdenum content, containing copper and nitrogen, and a typical microstructure of the base metal composed of 100% austenite is called a super austenitic stainless steel. Due to its high nickel and molybdenum content, as well as the presence of copper and nitrogen, super austenitic stainless steel is relatively difficult to melt; Super austenitic stainless steel is prone to segregation, cracking, and other issues, making it the most demanding and difficult variety in stainless steel production processes.

Like other commonly used Cr Ni austenitic steels, super austenitic stainless steel has excellent cold and hot workability.

(1) The maximum heating temperature during hot forging can reach 1180 degrees Celsius, and the minimum stopping forging temperature is not less than 900 degrees Celsius;

(2) Hot forming can be carried out at 1000-1150 degrees Celsius;

(3) The heat treatment process is 1100-1150 degrees Celsius, followed by rapid cooling after heating;

(4) Although universal welding techniques can be used for welding, the most appropriate welding methods are manual arc welding and tungsten inert gas welding.

Super Austenitic Stainless Steel includes: S30432,S31042,N0367,904L,Nitronic 40,Nitronic 60,XM-19 etc.

Classification and Characteristics:

(1) 6 Molybdenum Super Austenitic Stainless Steel

The molybdenum content is 6% or slightly higher, represented by AL-6XN and 254 SMO; The common feature of the 6-molybdenum super austenitic stainless steel family is that they all have very high resistance to pitting and crevice corrosion.

(2) 7 Molybdenum based Super Austenitic Stainless Steel

The molybdenum content is 7% or slightly higher, represented by 654 SMO; The anti-corrosion ability is comparable to the best nickel based alloys.

Super austenitic stainless steel pipes are renowned for their excellent corrosion resistance, high strength, and good welding performance. Its chemical composition has been carefully designed to achieve optimal corrosion resistance and mechanical properties. In addition, super austenitic stainless steel pipes also have excellent high-temperature resistance, allowing them to maintain stable performance in extreme environments.

In terms of application, super austenitic stainless steel pipes are widely used in multiple industries such as petroleum, chemical, pharmaceutical, and food. Due to its excellent corrosion resistance, super austenitic stainless steel pipes perform excellently in corrosive environments such as acid and alkali, effectively reducing equipment maintenance costs. In addition, the high strength and good welding performance of super austenitic stainless steel pipes also make them highly favored in pipeline engineering, providing strong guarantees for the smooth progress of various engineering projects.

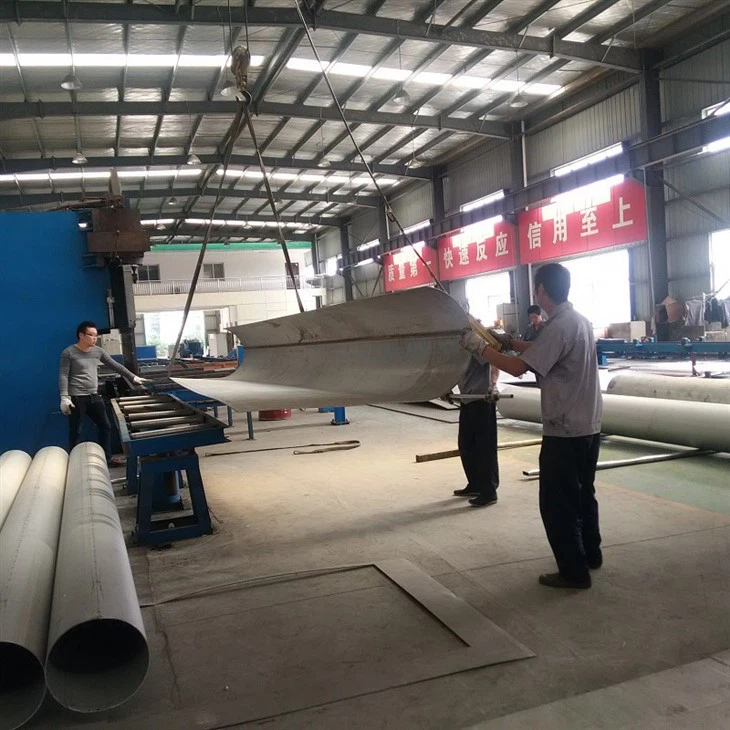

Our Services & Strength

We have advanced technology and equipment, strict detection means, scientific management to guarantee the high-quality, stability and reliability for every batch of product dispatched from the factory. Also, our company has many years of foreign trade experience and has established long term trade cooperation with many foreign companies. All of us are ready to start the business cooperation with you.

FAQ

1. who are we?

We are based in Hunan, China, start from 2003,sell to Southeast Asia(30.00%),South America(25.00%),Domestic Market(15.00%),North America(5.00%),Africa(5.00%),Mid East(5.00%),Oceania(3.00%),Eastern Asia(2.00%),Central America(2.00%),Northern Europe(2.00%),Southern Europe(2.00%),South Asia(2.00%),Eastern Europe(1.00%),Western Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

stainless steel pipe,casing and tubing and forging,Nickel based alloy steel pipe,AMS standard tube and bar,any machined part with drawings,processing services

4. why should you buy from us not from other suppliers?

Strong financial support:we can handle max amount 100-500 million dollars for an order.

Rich experienced marketing team/production team/after-sales team

We can provide you with all the required documents when the tender is in progress.

Type | Seamless/Welded |

Shape | Square / Rectangular / Round |

Standard | GB,AISI,ASTM,DIN,EN,JIS |

Available Grades | Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. |

Monel 400 / Monel K-500 | |

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

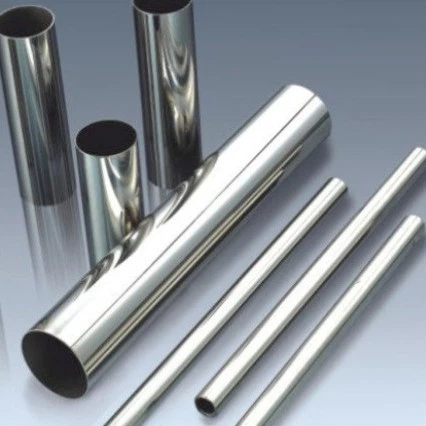

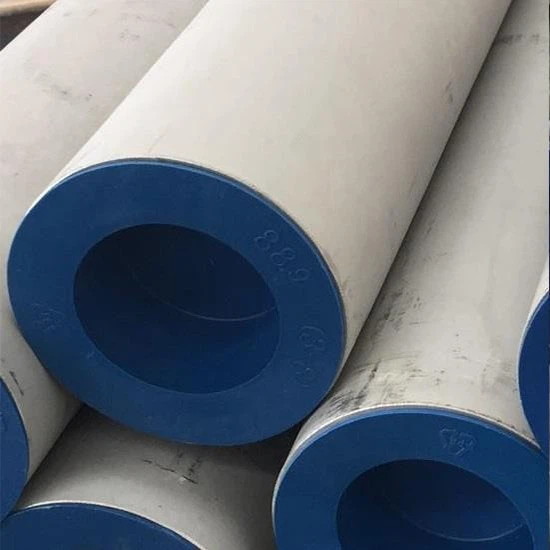

Out diameter | Seamless Pipe 6MM - 1174MM or customized |

Thickness | Seamless Pipe 1mm - 80mm or customized |

Max Length | Seamless Pipe 12000mm or customized |

Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

Inspection | TUV,SGS,BV,ABS,LR and so on |

Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

Deformation processing : Bending / Cutting / Rolling / Stamping | |

Welded | |

Forged | |

Delivery | 7-40 days |

Trade Term | FOB CIF CFR CIP DAP DDP EXW |

Transportation | By air, by sea, by train, by truck |

Sample | Free |

Warranty | Trade assurance after sales service |

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, super austenitic stainless steel pipe, China super austenitic stainless steel pipe manufacturers, suppliers, factory, Nickel Alloy Precision Tube, Nickel Alloy EP Tube, Stainless Steel Ring Forging, Stainless Steel Precision Tube, Nickel Alloy Capillary T,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More