Stainless Steel Corrugated Pipe

Stainless steel corrugated pipe, as a flexible and pressure resistant pipe fitting installed in liquid transportation systems, is used to compensate for the mutual displacement of pipes, machines, and

Description

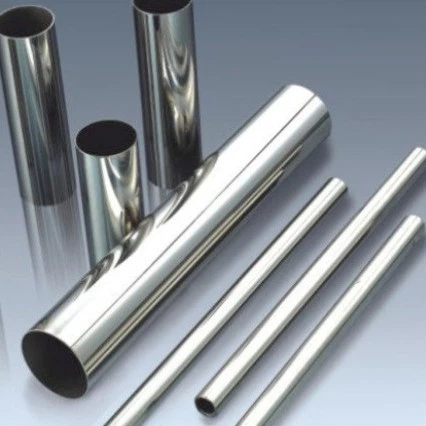

Stainless steel corrugated pipe, as a flexible and pressure resistant pipe fitting installed in liquid transportation systems, is used to compensate for the mutual displacement of pipes, machines, and equipment connection ends, absorb vibration energy, and can play a role in vibration reduction, noise reduction, etc. It has multiple characteristics such as good flexibility, light weight, corrosion resistance, fatigue resistance, and high and low temperature resistance.

The stiffness of a metal bellows is the load value required to produce a unit displacement of the metal bellows or other elastic components, which is called the stiffness of the component and is generally represented by "K". If the elastic properties of the component are nonlinear, the stiffness is no longer a constant, but changes with increasing load. The stiffness given in the design and calculation of elastic elements with nominal stiffness is called nominal (or rated) stiffness. It has errors with the measured stiffness of the element, especially for elastic elements with nonlinear elastic characteristics. The nominal stiffness represents the stiffness at which point on the curve, which needs to be carefully considered. Generally speaking, it is best not to directly use the design calculation value for nominal stiffness, but rather to use the corrected value of the product prototype after testing. The allowable deviation of stiffness for a batch of elastic components during testing is the allowable range of stiffness dispersion. For the same batch of elastic components, the stiffness of each component of the stainless steel metal hose is not the same, with a dispersed range. In order to ensure the performance of the components, it is necessary to have a limit on the range of stiffness dispersion. For elastic sensitive components, the stiffness tolerance requirement is limited to within+/-5% of the nominal value; The stiffness tolerance of corrugated pipe elastic components used in general engineering can be limited within+/-50%.

Characteristics of stainless steel corrugated pipes

1. Corrosion resistance: Stainless steel corrugated pipes are made of high-quality stainless steel materials, which have extremely strong corrosion resistance and can be used for a long time in various harsh environments, reducing maintenance costs.

2. High strength: Stainless steel corrugated pipes have undergone special processing and have high strength and toughness, which can withstand large pressures and impacts, ensuring the safe operation of the pipeline.

3. High temperature resistance: Stainless steel corrugated pipes have good high temperature resistance, which can maintain stable performance in high temperature environments and extend the service life of pipelines.

4. Good sealing performance: The stainless steel corrugated pipe adopts a unique corrugated design, which can effectively prevent liquid and gas leakage, ensuring the sealing performance of the pipeline.

The application of stainless steel corrugated pipes

1. Building water supply and drainage: Stainless steel corrugated pipes are widely used in building water supply and drainage systems, such as water supply, drainage, fire protection and other pipeline systems in high-rise buildings, effectively improving the safety and reliability of water supply and drainage systems.

2. Air conditioning refrigeration: Stainless steel corrugated pipes play a crucial role in air conditioning refrigeration systems, such as condensate discharge, refrigerant transfer, etc., to ensure the efficient operation of the air conditioning refrigeration system.

3. Thermal energy engineering: Stainless steel corrugated pipes have a wide range of applications in thermal energy engineering, such as hot water supply, steam transmission, etc., effectively improving the efficiency and safety of thermal energy transmission.

4. Chemical industry: Stainless steel corrugated pipes play a crucial role in the chemical industry, such as the transportation of corrosive media and the connection of reactors, to ensure the stability and safety of chemical production.

The commonly used grades are:

Austenitic Stainless Steel:304,304H,304L,316L,316H,316Ti,317,317L,321,347,347H,347HFG,310S,310H,

Super Austenitic Stainless Steel: S30432,S31042,N0367,904L,Nitronic 40,Nitronic 60,XM-19

Duplex Stainless Steel: 254SMO,F50,2205,F53,F55,F60,F61,F65,S31500,S31803,S32205,S32750,S32760

PH Steel: 15-5PH,17-4PH,17-7PH,13-8MO

Type | Welded / Seamless |

Shape | Square / Rectangular / Round |

Standard | GB,AISI,ASTM,DIN,EN,JIS |

Available Grades | Seamless tube: EN 10216-5, NFA 49-217 |

Seamless and welded tube: ASTM A789 | |

Flanges and valves: ASTM A182 | |

Fittings: ASTM A182; A815 | |

Plate, sheet and strip: ASTM A240, EN 10088-2 | |

Bar and shapes: ASTM A276, A479, EN 10088-3 | |

Forged billets: EN 10088-3 | |

Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. | |

Monel 400 / Monel K-500 | |

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

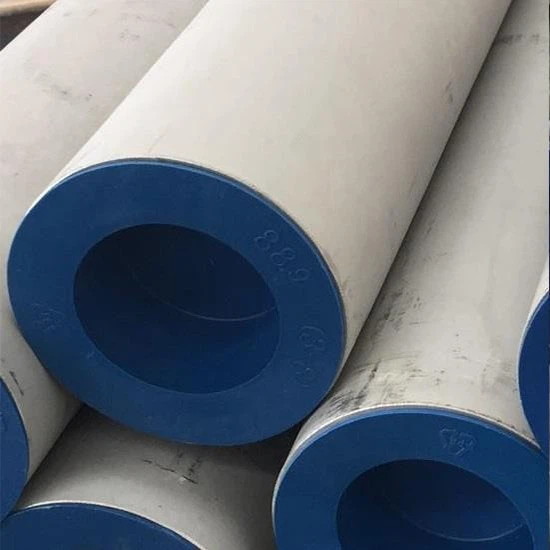

Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

Thickness | Welded Pipe 0.5mm - 80mm or customized |

Max Length | Welded Pipe 50000mm or customized |

Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

Inspection | TUV,SGS,BV,ABS,LR and so on |

Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

Deformation processing : Bending / Cutting / Rolling / Stamping | |

Welded | |

Forged | |

Delivery Time | 7-40 days |

Trade Term | FOB CIF CFR CIP DAP DDP EXW |

Transportation | By air, by sea, by train, by truck |

Sample | Free |

Warranty | Trade assurance after sales service |

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, stainless steel corrugated pipe, China stainless steel corrugated pipe manufacturers, suppliers, factory, Stainless Steel Ring Forging, Stainless Steel Pipe And Tube, Stainless Steel Wheel Forging, Nickel Alloy Capillary Tube, Hastelloy Series Pipe, Nicke,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More