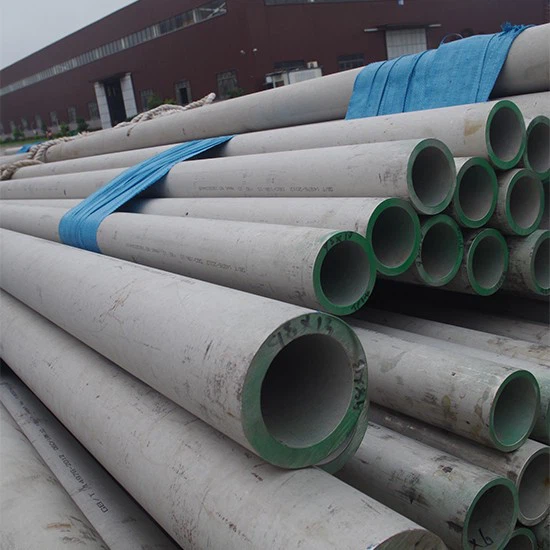

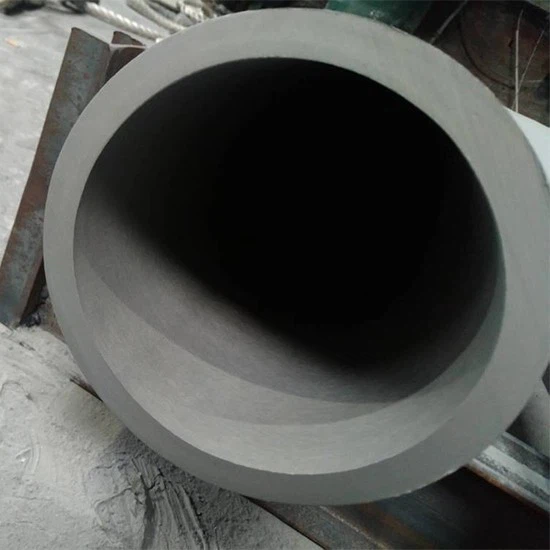

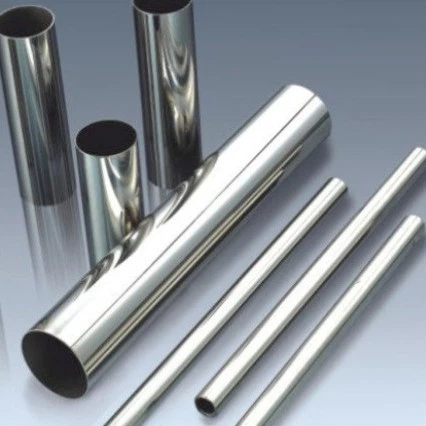

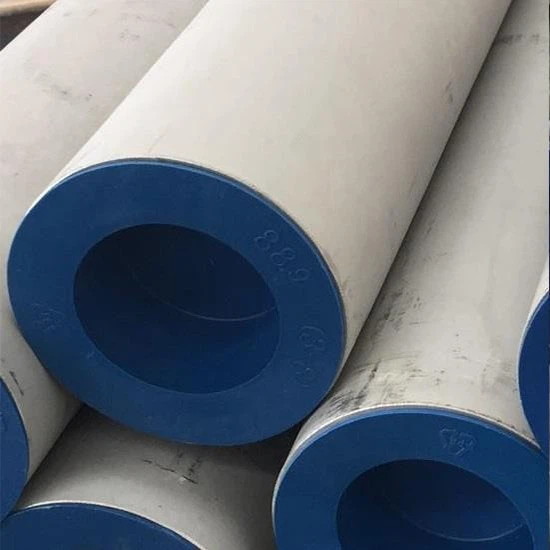

Stainless Steel Thick Wall Seamless Pipe

Stainless steel seamless steel pipe is a long strip of steel with a hollow cross-section and no seams around it. It is a steel pipe that is resistant to weak corrosive media such as air, steam, water,

Description

Stainless steel seamless steel pipe is a long strip of steel with a hollow cross-section and no seams around it. It is a steel pipe that is resistant to weak corrosive media such as air, steam, water, and chemical corrosive media such as acid, alkali, and salt. Also known as stainless acid resistant steel pipe.

Stainless steel thick wall seamless pipes have the following significant characteristics:

1. Corrosion resistance: Stainless steel thick walled seamless steel pipes have extremely high corrosion resistance and can maintain stable performance in various harsh environments.

2. High strength: The thick wall design enables stainless steel thick walled seamless steel pipes to have higher strength and can withstand greater pressure and loads.

3. Good thermal conductivity: Stainless steel thick walled seamless steel pipes have excellent thermal conductivity and are suitable for various applications in high and low temperature environments.

4. Easy to process and install: Stainless steel thick walled seamless steel pipes have good processing performance, are easy to cut, bend, and weld, and reduce installation and maintenance costs.

Stainless steel thick wall seamless pipes are widely used in the following fields:

1. Petrochemical industry: Stainless steel thick walled seamless steel pipes are used in the petrochemical industry to transport corrosive media such as acid and alkali, ensuring the safety and stability of the production process.

2. Power industry: Stainless steel thick walled seamless steel pipes are used in the power industry to transport media such as steam and water in high-temperature and high-pressure environments, ensuring efficient and safe power production.

3. Building water supply and drainage: Stainless steel thick walled seamless steel pipes are used in the field of building water supply and drainage to transport domestic water and fire water, ensuring water quality safety and service life.

4. Food and pharmaceutical: Stainless steel thick walled seamless steel pipes are used in the food and pharmaceutical industry to transport various food and pharmaceutical raw materials, ensuring the hygiene and safety of the production process.

The commonly used grades are:

Austenitic Stainless Steel:304,304H,304L,316L,316H,316Ti,317,317L,321,347,347H,347HFG,310S,310H,

Super Austenitic Stainless Steel: S30432,S31042,N0367,904L,Nitronic 40,Nitronic 60,XM-19

Duplex Stainless Steel: 254SMO,F50,2205,F53,F55,F60,F61,F65,S31500,S31803,S32205,S32750,S32760

PH Steel: 15-5PH,17-4PH,17-7PH,13-8MO

Type | Seamless |

Shape | Square / Rectangular / Round |

Standard | GB,AISI,ASTM,DIN,EN,JIS |

Available Grades | Seamless tube: EN 10216-5, NFA 49-217 |

Seamless and welded tube: ASTM A789 | |

Flanges and valves: ASTM A182 | |

Fittings: ASTM A182; A815 | |

Plate, sheet and strip: ASTM A240, EN 10088-2 | |

Bar and shapes: ASTM A276, A479, EN 10088-3 | |

Forged billets: EN 10088-3 | |

Stainless steel 301 / 302 / 303 / 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 321 / 32760 / 253MA / 254SMo / 410 / 420 / 430 / Custom465 / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65. | |

Monel 400 / Monel K-500 | |

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 / Inconel 713C / Inconel 713LC | |

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

Thickness | Welded Pipe 0.5mm - 80mm or customized |

Max Length | Welded Pipe 50000mm or customized |

Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

Inspection | TUV,SGS,BV,ABS,LR and so on |

Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

Deformation processing : Bending / Cutting / Rolling / Stamping | |

Welded | |

Forged | |

Delivery Time | 7-40 days |

Trade Term | FOB CIF CFR CIP DAP DDP EXW |

Transportation | By air, by sea, by train, by truck |

Sample | Free |

Warranty | Trade assurance after sales service |

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, stainless steel thick wall seamless pipe, China stainless steel thick wall seamless pipe manufacturers, suppliers, factory, Chemical Industry Seamless Pipe, Stainless Steel EP Tube, Stainless Steel Rectangular Tube, Forgings And Castings, Stainless Steel,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More