Polishing Service

There are several commonly used polishing methods:1. Mechanical polishingMechanical polishing is a polishing method that obtains a smooth surface by removing the protrusions after polishing through cu

Description

There are several commonly used polishing methods:

1. Mechanical polishing

Mechanical polishing is a polishing method that obtains a smooth surface by removing the protrusions after polishing through cutting and plastic deformation of the material surface. It generally uses oilstone strips, wool wheels, sandpaper, etc., and is mainly operated by hand and angle grinder. Special parts such as the surface of the rotating body can be polished using auxiliary tools such as turntables. For those with high surface quality requirements, ultra precision polishing can be used. Ultra precision polishing is the use of specially designed grinding tools, which press tightly on the surface of the workpiece in a polishing fluid containing abrasives and perform high-speed rotational motion.

2. Chemical polishing

Chemical polishing is the process of allowing the surface of a material to preferentially dissolve the concave parts of the surface that protrude in a chemical medium, thereby obtaining a smooth surface. The main advantage of this method is that it does not require complex equipment and can polish workpieces with complex shapes. It can simultaneously polish many workpieces with high efficiency. The core issue of chemical polishing is the preparation of polishing solution. By selectively dissolving the small protrusions on the surface of the material, the surface becomes smooth.

3. Electrochemical polishing

Compared with chemical polishing, it can eliminate the influence of cathodic reactions and achieve better results. The electrochemical polishing process is divided into two steps: (1) macroscopic leveling, dissolution products diffuse into the electrolyte, and the geometric roughness of the material surface decreases. (2) Low light level anodizing improves surface brightness.

4. Ultrasonic polishing

Put the workpiece into the abrasive suspension and place it together in the ultrasonic field, relying on the oscillation effect of the ultrasonic wave to grind and polish the abrasive on the surface of the workpiece. Ultrasonic machining has low macroscopic force and will not cause deformation of the workpiece, but it is difficult to make and install fixtures. Ultrasonic processing can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, ultrasonic vibration is applied to stir the solution, causing the dissolution products on the surface of the workpiece to detach and the corrosion or electrolyte near the surface to be uniform; The cavitation effect of ultrasound in liquids can also suppress the corrosion process and facilitate surface gloss.

5. Fluid polishing

Fluid polishing relies on the high-speed flow of liquid and its carried abrasive particles to flush the surface of the workpiece to achieve the purpose of polishing. Common methods include abrasive jet machining, liquid jet machining, fluid dynamic grinding, etc. Fluid dynamic grinding is driven by hydraulic pressure, which causes the liquid medium carrying abrasive particles to flow back and forth at high speed through the surface of the workpiece. The medium is mainly made of special compounds (polymer like substances) with good flowability under lower pressure and mixed with abrasives, which can use silicon carbide powder.

6. Magnetic grinding and polishing

Magnetic abrasive polishing is the process of using magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind and process workpieces. This method has high processing efficiency, good quality, easy control of processing conditions, and good working conditions. By using appropriate abrasives, the surface roughness can reach Ra0.1 μ M. However, the surface quality of methods such as chemical polishing, ultrasonic polishing, and magnetic grinding polishing cannot meet the requirements, so mechanical polishing is still the main method for precision molds.

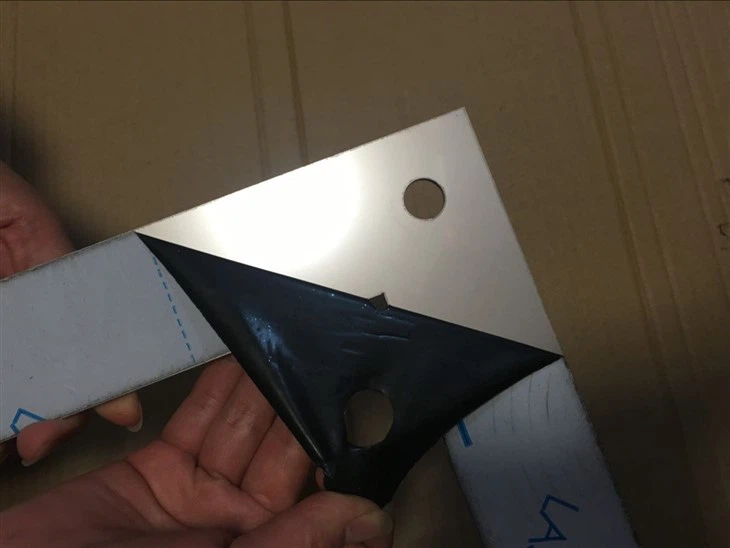

Polishing surface processing for stainless steel sheet and plate:

No.3: Represented by 3A and 3B.

3A: The surface is uniformly ground with an abrasive particle size of 80-100.

3B: Rough surface polishing with uniform straight lines on the surface, usually achieved by one-time polishing with a grit size of 180-200 on a 2A or 2B board.

No.4: Unidirectional surface processing, with weak reflectivity, may be the most widely used in construction applications. The process steps are to first polish with coarse abrasive, and finally grind with abrasive with a particle size of 180.

No.6: It is a further improvement on No.4, which involves polishing the surface of No.4 with a Tempico polishing brush in abrasive and oil media. The surface finish is not included in British Standard 1449, but can be found in American standards.

No.7: It is called glossy polishing, which is the polishing of a surface that has been finely ground but still has scratches. Usually, 2A or 2B boards are used, with fiber or cloth polishing wheels and corresponding polishing paste.

No.8: Mirror polished surface, with high reflectivity, is commonly referred to as mirror surface processing because it reflects clear images. Continuously polish stainless steel with fine abrasive, and then use very fine polishing paste for polishing. In architectural applications, it should be noted that if this surface is used in areas with high personnel flow or frequently touched by people, it will leave fingerprints. Of course, fingerprints can be wiped off, but sometimes it affects aesthetics.

Our Services & Strength

We have advanced technology and equipment, strict detection means, scientific management to guarantee the high-quality, stability and reliability for every batch of product dispatched from the factory. Also, our company has many years of foreign trade experience and has established long term trade cooperation with many foreign companies. All of us are ready to start the business cooperation with you.

FAQ

1. who are we?

We are based in Hunan, China, start from 2003,sell to Southeast Asia(30.00%),South America(25.00%),Domestic Market(15.00%),North America(5.00%),Africa(5.00%),Mid East(5.00%),Oceania(3.00%),Eastern Asia(2.00%),Central America(2.00%),Northern Europe(2.00%),Southern Europe(2.00%),South Asia(2.00%),Eastern Europe(1.00%),Western Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

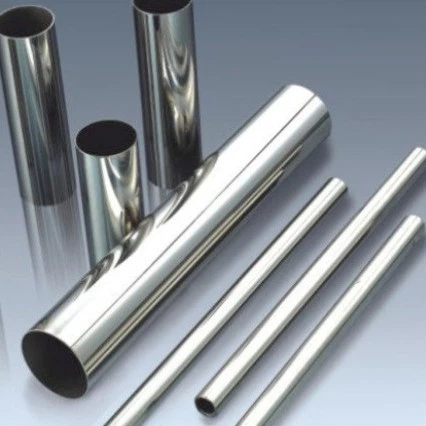

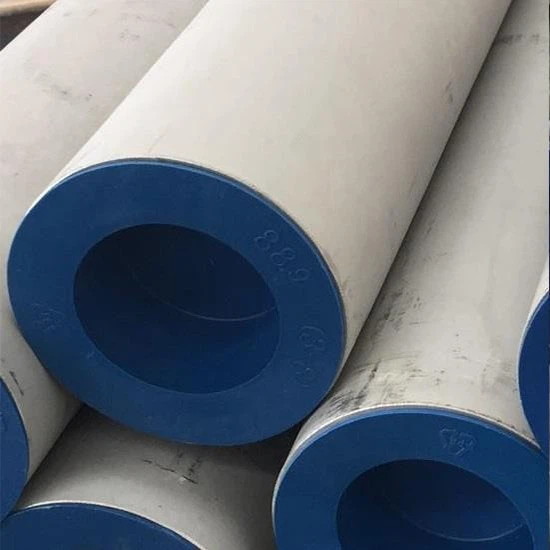

stainless steel pipe,casing and tubing and forging,Nickel based alloy steel pipe,AMS standard tube and bar,any machined part with drawings,processing services

4. why should you buy from us not from other suppliers?

Strong financial support:we can handle max amount 100-500 million dollars for an order.

Rich experienced marketing team/production team/after-sales team

We can provide you with all the required documents when the tender is in progress.

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, polishing service, China polishing service manufacturers, suppliers, factory, Stainless Steel Capillary Tube, Stainless Steel Rectangular Tube, Nickel Alloy Petroleum Forging, Nickel Alloy Barrel Forging, Super Austenitic Stainless Steel Pipe,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More