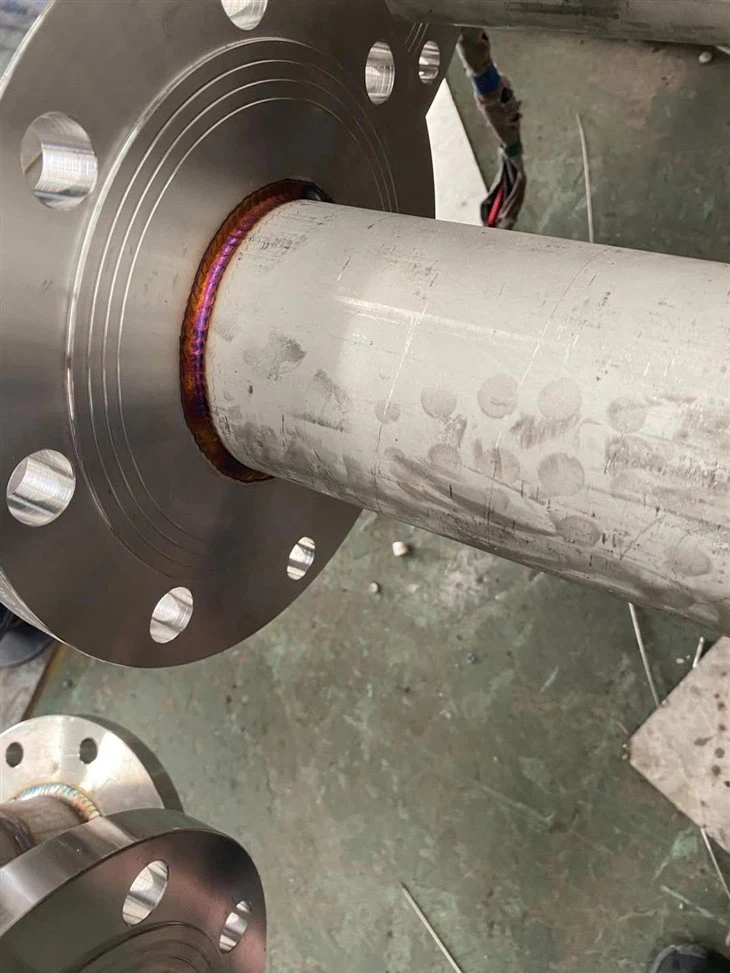

Welding Service

Stainless steel welding services are a professional service widely used in fields such as construction, chemical engineering, and healthcare. With the continuous development of technology, stainless s

Description

Stainless steel welding services are a professional service widely used in fields such as construction, chemical engineering, and healthcare. With the continuous development of technology, stainless steel welding technology is also constantly improving and innovating, providing more reliable and efficient solutions for various industries. Stainless steel welding services include advanced technologies such as laser welding and gas shielded welding.

Stainless steel welding service refers to the use of special welding techniques and equipment to connect stainless steel materials together, forming structures or devices with excellent performance. Stainless steel welding services have been widely used in fields such as construction, chemical engineering, and healthcare, providing reliable solutions for various industries.In recent years, significant progress has been made in stainless steel welding technology. For example, laser welding technology achieves high-quality and efficient welding effects by locally melting and rapidly cooling stainless steel with high-energy laser beams. In addition, gas shielded welding technology effectively prevents adverse reactions such as oxidation and nitriding by using inert gases such as argon to protect the weld seam, improving welding quality.

Key points of stainless steel welding process technology

Stainless steel welded pipes are formed by rolling and welding stainless steel plates through a roller mold on a welding pipe forming machine. Due to the high strength of stainless steel and its face centered cubic lattice structure, it is easy to form work hardening, which makes the mold susceptible to wear and tear during the formation of welded pipes; On the other hand, stainless steel sheets are prone to bonding (biting) with the surface of the mold, causing strains on the welded pipe and mold surfaces. Therefore, a good stainless steel forming mold must have extremely high wear resistance and anti adhesion (bite) performance. Our analysis of imported welded pipe molds shows that the surface treatment of such molds is to use superhard metal carbide or nitride coating treatment.

Compared with traditional melting welding, laser welding and high-frequency welding have the characteristics of fast welding speed, high energy density, and low heat input. Therefore, the heat affected zone is narrow, the degree of grain growth is small, the welding deformation is small, the cold processing formability is good, and it is easy to achieve automated welding and single pass penetration of thick plates. The most important feature is that I-groove butt welding does not require filling materials.

Welding technology is mainly applied to metal base materials, commonly including arc welding, argon arc welding, CO2 shielded welding, oxygen acetylene welding, laser welding, electric slag pressure welding, etc. Non metallic materials such as plastics can also be welded. There are over 40 types of metal welding methods, mainly divided into three categories: fusion welding, pressure welding, and brazing.

Fusion welding is a method of heating the workpiece interface to a molten state during the welding process, without applying pressure to complete the welding. During fusion welding, the heat source rapidly heats and melts the interface between the two workpieces to be welded, forming a molten pool. The molten pool moves forward with the heat source and forms a continuous weld after cooling, connecting the two workpieces into one.

During the welding process, if the atmosphere comes into direct contact with the high-temperature molten pool, the oxygen in the atmosphere will oxidize the metal and various alloying elements. Nitrogen and water vapor from the atmosphere entering the molten pool can also form defects such as pores, slag inclusions, and cracks in the weld seam during subsequent cooling, deteriorating the quality and performance of the weld seam.

Pressure welding is the process of achieving atomic bonding between two workpieces in a solid state under pressure, also known as solid-state welding. The commonly used pressure welding process is resistance welding. When current passes through the connection end of two workpieces, the temperature rises due to the high resistance. When heated to a plastic state, the connection becomes integrated under axial pressure.

The common feature of various pressure welding methods is to apply pressure during the welding process without adding filler material. Most pressure welding methods such as diffusion welding, high-frequency welding, cold pressure welding, etc. do not have a melting process, so there is no problem of beneficial alloy element burning and harmful element invasion into the weld seam like fusion welding, which simplifies the welding process and improves welding safety and hygiene conditions. Meanwhile, due to the lower heating temperature and shorter heating time compared to fusion welding, the heat affected zone is smaller. Many materials that are difficult to melt weld can often be pressure welded into high-quality joints with the same strength as the base material.

Brazing is a welding method that uses a metal material with a lower melting point than the workpiece as the brazing material. The workpiece and brazing material are heated to a temperature higher than the melting point of the brazing material but lower than the melting point of the workpiece. The liquid brazing material is used to wet the workpiece, fill the interface gap, and achieve atomic diffusion with the workpiece, thereby achieving welding.

The joint formed during welding that connects two connected bodies is called a weld seam. The two sides of the weld seam will be subjected to welding heat during welding, resulting in changes in microstructure and properties. This area is called the heat affected zone. During welding, due to differences in workpiece material, welding material, welding current, etc., overheating, embrittlement, quenching or softening may occur in the weld seam and heat affected zone after welding, which can also lead to a decrease in the performance of the welded part and deteriorate the weldability. This requires adjusting the welding conditions. Preheating the interface of the weldment before welding, insulation during welding, and post weld heat treatment can improve the welding quality of the weldment.

Types of welding techniques for stainless steel pipes

Welding process adopted: Using small specifications can prevent intergranular corrosion, hot cracking, and deformation, and the welding current is 20% lower than that of low carbon steel; To ensure stable arc combustion, DC reverse connection is adopted; Short arc welding should be stopped slowly, fill the arc pit, and finally weld the surface in contact with the medium; During multi-layer welding, the interlayer temperature should be controlled, and forced cooling can be adopted after welding; Do not start an arc outside the groove, and connect the ground wire properly; Post weld deformation can only be corrected by cold working.

1) Argon arc welding

When using argon arc welding for stainless steel, due to its good protective effect, alloy elements are not easily burned, and the transition coefficient is high, the weld seam is formed well, without slag shell, and the surface is smooth. Therefore, the welded joint has high heat resistance and good mechanical properties. Currently, the most widely used method in argon arc welding is manual tungsten inert gas welding, which is used to weld stainless steel thin plates of 0.5-3mm. The composition of the welding wire is generally the same as that of the workpiece, and industrial pure argon gas is generally used as the shielding gas. The welding speed should be appropriately fast to avoid lateral swinging as much as possible. For stainless steel with a thickness greater than 3mm, melting electrode argon arc welding can be used. The advantages of melting electrode argon arc welding are high productivity, small heat affected zone of the weld, small deformation of the welded part, good corrosion resistance, and easy automation operation.

2) Gas welding

Due to its convenience and flexibility, gas welding can be used to weld seams in various spatial positions. For some stainless steel components such as thin plate structures and thin-walled pipes, gas welding can sometimes be used without corrosion resistance requirements. To prevent overheating, the welding nozzle is generally smaller than when welding low carbon steel of the same thickness. A neutral flame should be used for gas welding, and the welding wire should be selected according to the composition and performance of the weldment. Gas welding powder should use gas agent 101. It is best to use the left welding method during welding. The inclination angle between the welding nozzle and the weldment should be 40-50 °, and the distance between the flame core and the molten pool should not be less than 2mm. The end of the welding wire should be in contact with the molten pool and move along the weld seam with the flame. The welding torch should not swing laterally, the welding speed should be fast, and interruptions should be avoided as much as possible.

3) Submerged arc welding

Submerged arc welding is suitable for welding stainless steel plates of medium thickness and above (6-50mm). Submerged arc welding has high productivity and good weld quality, but it is prone to segregation of alloy elements and impurities.

4) Manual welding

Manual welding is a very common and easy-to-use welding method The length of the arc is adjusted by human hands and is determined by the size of the gap between the welding electrode and the workpiece Meanwhile, when used as an arc carrier, the welding electrode is also a filler material for the weld seam.

This welding method is very simple and can be used to weld almost all materials For outdoor use, it has good adaptability, even when used underwater Most welding machines can perform TIG welding In electrode welding, the arc length is determined by the human hand: when you change the gap between the electrode and the workpiece, you also change the arc length In most cases, direct current is used for welding, and the electrode serves as both the arc carrier and the filler material for the weld seam The electrode is composed of alloy or non alloy metal core wire and electrode coating This layer of coating protects the weld from air damage and stabilizes the arc It also causes the formation of slag layer, protecting the weld seam and shaping it The welding electrode can be a titanium type electrode or a sealed electrode, depending on the thickness and composition of the coating Titanium type welding rods are easy to weld, and the weld seam is flat and beautiful In addition, welding slag is easy to remove If the welding rod is stored for a long time, it must be baked again Because moisture from the air can quickly accumulate in the welding rod.

5) MIG/MAG welding

This is an automatic gas shielded arc welding method In this method, the arc is burned between the current carrier wire and the workpiece under a protective gas shield The metal wire fed into the machine serves as a welding rod and melts under its own arc Due to the advantages of universality and specificity of MIG/MAG welding method, it is still the most widely used welding method in the world today It is used for materials based on steel, non alloy steel, low alloy steel, and high alloy This makes it an ideal welding method for production and repair When welding steel, MAG can meet the requirements of thin specification steel plates with a thickness of only 0.6mm The protective gas used here is an active gas, such as carbon dioxide or a mixture of gases The only limitation is that when performing outdoor welding, the workpiece must be protected from moisture to maintain the effectiveness of the gas.

6) TIG welding

An arc is generated between the refractory tungsten welding wire and the workpiece The protective gas used here is pure argon gas, and the incoming welding wire is not charged Welding wire can be manually or mechanically fed There are also some specific uses that do not require the use of welding wire The material being welded determines whether direct current or alternating current is used When using direct current, tungsten welding wire is set as the negative electrode Because it has a deep penetration ability, it is suitable for different types of steel, but it has no "cleaning effect" on the weld pool.

Inspection method for stainless steel welding process

The welding inspection includes the inspection of materials, tools, equipment, processes, and finished product quality used throughout the entire production process from drawing design to product manufacturing. It is divided into three stages: pre welding inspection, inspection during the welding process, and inspection of the finished product after welding. The inspection methods can be divided into destructive testing and non-destructive testing based on whether they cause damage to the product.

1) Pre weld inspection

Pre weld inspection includes inspection of raw materials (such as base metal, welding rod, flux, etc.), inspection of welding structure design, etc.

2) Inspection during welding process

Including inspection of welding process specifications, inspection of weld seam dimensions, inspection of fixture conditions and structural assembly quality, etc.

3) Inspection of finished products after welding

There are many methods for inspecting finished products after welding, and the commonly used ones include the following:

Appearance inspection

The appearance inspection of welded joints is a simple and widely used inspection method, which is an important part of finished product inspection, mainly to discover defects and dimensional deviations on the surface of the weld seam. Generally, inspection is carried out through visual observation, using tools such as standard templates, gauges, and magnifying glasses. If there are defects on the surface of the weld seam, there is a possibility of defects inside the weld seam.

Density test

The non dense defects in the welds of welded containers storing liquids or gases, such as penetrating cracks, pores, slag inclusions, lack of penetration, and loose structure, can be detected by density testing. The methods for testing density include kerosene test, water carrying test, water flushing test, etc.

Strength testing of pressure vessels

Pressure vessels must undergo strength tests in addition to sealing tests. There are two common types: hydrostatic test and pneumatic test. They can all test the weld tightness of containers and pipelines working under pressure. Pneumatic testing is more sensitive and rapid than hydraulic testing, and the tested products do not require drainage treatment, making it particularly suitable for products with difficult drainage. But the danger of testing is greater than that of hydrostatic testing. When conducting experiments, corresponding safety technical measures must be followed to prevent accidents from occurring during the testing process.

Verification of physical methods

The physical testing method is a method of measuring or testing using some physical phenomena. The inspection of internal defects in materials or workpieces is generally carried out using non-destructive testing methods. At present, non-destructive testing includes ultrasonic testing, radiographic testing, penetrant testing, magnetic testing, etc.

① Radiographic testing

Radiographic testing is a method of detecting defects by utilizing the penetrability and attenuation properties of radiation in materials. According to the different types of radiation used for testing, it can be divided into three types: X-ray testing, gamma ray testing, and high-energy ray testing. Due to different methods of displaying defects, each type of radiographic inspection is further divided into ionization method, fluorescent screen observation method, photographic method, and industrial television method. Radiographic inspection is mainly used to detect defects such as cracks, incomplete penetration, porosity, slag inclusion, etc. inside the weld seam.

② Ultrasonic testing

Ultrasonic waves can be used for the inspection of internal defects in metals and other homogeneous media due to reflection at the interface of different media. Ultrasonic waves can inspect any welding material and any part of the defect, and can sensitively detect the location of the defect, but it is difficult to determine the nature, shape, and size of the defect. So ultrasonic testing is often used in conjunction with radiographic testing.

③ Magnetic testing

Magnetic inspection is the use of magnetic fields to magnetize ferromagnetic metal parts and detect defects by generating leakage magnetism. According to the different methods of measuring magnetic leakage, they can be divided into magnetic particle method, magnetic induction method, and magnetic recording method, among which the magnetic particle method is the most widely used.

Magnetic testing can only detect defects on the surface and near surface of magnetic metals, and can only perform quantitative analysis on defects. The nature and depth of defects can only be estimated based on experience.

④ Penetration inspection

Penetration inspection is the use of physical properties such as the permeability of certain liquids to detect and display defects, including dye penetrant inspection and fluorescent testing, which can be used to inspect defects on the surfaces of ferromagnetic and non-magnetic materials.

Hot Tags: seamless stainless steel pipe, China seamless stainless steel pipe manufacturers, suppliers, factory, welding service, China welding service manufacturers, suppliers, factory, Stainless Steel Precision Tube, Stainless Steel Rectangular Tube, Inconel Series Pipe, Forgings And Castings, Nickel Alloy Ring Forging, Stainless Steel Shaft Forging,

Categories

Hot Products

-

Stainless Steel Decorative Tube

Read more -

Stainless Steel Rectangular Tube

Read more -

Stainless Steel Square Tube

Read more -

Super Austenitic Stainless Steel Pipe

Read more -

Stainless Steel Oval Tube

Read more -

Stainless Steel EP Tube

Read more -

Stainless Steel BA Tube

Read more -

Stainless Steel Thick Wall Seamless Pipe

Read more -

Stainless Steel Tube Bending

Read more -

Stainless Steel Corrugated Pipe

Read more

Send Message

Cookie Policy

In order to provide you with a better browsing experience, this website will use cookies. By clicking "Accept" or continuing to browse this website, you agree to our use of cookies.Learn More